|

FAQs about Stands, Supports for

Aquariums: DIY

Related Articles: Aquarium Stands, Marine

Tanks, Canopies, Covers &

Lighting Fixtures,

Related FAQs: Aquarium Stands 1, Aquarium Stands 2, What to Use, About

Floors Underneath, Finishing/Coating, Commercial, Leveling, Modification, Repair, & Tanks, Tanks 2,

Tanks 3, Tanks 4, Aquarium

Repair 1, Acrylic Aquarium

Repair, Used Aquarium

Gear,

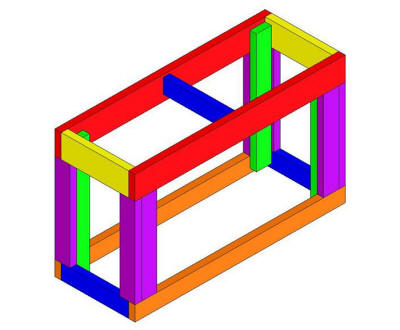

PLENTY of room underneath

for gear, manipulation. JasonC's set-up in FLA

|

|

|

Two birds with one stone. Stand/tank minor gap, cleaning old dry

LR 9/16/16

Hi WWM Crew,

<Hey Eddie>

As always I am eternally grateful to you all for your patient assistance.

Your website is a treasure trove of aquarium knowledge. Every time I visit I

come away richer. I have been “dry” for almost four years now, but still

considering myself a part of the saltwater hobby. I’m getting ready to get

“wet” again, and I have a LOT of questions to ask so that I do it right this

time. I’ve been studying WWM (and other sources) for several years, but

often with greater learning comes only more finely honed questions. Today I

have two sets of such questions. I guess this is a “two birds with one

stone” type email.

<Let's see>

It’s been a while since I have asked a question, and I have been busy. I’ve

been at work building a stand for my 75 gallon tank.

<I see this in your pic. REALLY like the fastener pattern>

I wanted to do this stand right because my last stand (for my old 55 gallon)

was not made right and eventually resulted in the catastrophic failure of

the bottom of the tank. I did a ton of research on how to do it, and this

(picture) is what I came up with. I’m kind of proud of it. What you see is

the finished frame for the stand. I have already treated it with spar

urethane. I also have some quarter inch oak plywood and trim that I will use

to “skin” it (and I’ll treat that with urethane as well). While I’m working

on the skin though, I thought I would go ahead and use the frame of the

stand for a water test on my tank. It’s a slightly used glass tank with an

offset overflow (as you can see from where the cutout in the stand top is

located).

<Good idea>

The stand frame is level, and when I sat the tank on it found that it is

almost perfectly planar. On one side there was a tiny gap running several

inches where I could slide a driver’s license fairly snugly.

<This is with the tank empty? I'd fill it; see if the gap

diminishes/disappears>

At widest I would estimate it to be 1/32nd of an inch. The reason for this

is something I found out after I built the stand, but something that I’ll

pass on to any DIY-ers who read this FAQ. When boards (2x4’s, etc.) are

planed, often the very end of the board is slightly thinner than the

rest—from where it tilts slightly under its own weight coming out of the

planer. It would be wise when working with wood to cut off the last inch or

two off the end of the board to avoid this (like for the top side rails of

an aquarium stand). This is the reason for that slight dip.

<Ahh!>

I was going to use Styrofoam anyway, which brings me to my first series of

questions. I bought some ¼ inch Styrofoam sheets from Lowe’s that are 4 feet

long. I was not thinking about the fact that my stand is 48 and ½ inches

long—so the Styrofoam will not cover the entire bottom of the stand. Will

the Styrofoam “spread out” under the weight to cover this gap?

<Mmm, not likely; no>

Or (because the tank has a floating bottom) should I cut the Styrofoam into

strips—say 2 inches wide? I could have two 48 X 2 inch strips and two 18 ½ X

2 inch strips (trimmed to fit together at the corners).

<I would cut such a strip; to cover the entire 48.5" base>

I got several sheets of the Styrofoam, and I planned to use some for the

test fill (which will last a week or two at least—it will be out of the way

in the basement), and then replace it when I set up the tank. Is it even

necessary to use it for the test fill?

<I would risk filling w/o w/ the small gap you're experiencing; but if you

feel uncomfortable, insert the foam.>

I don’t want to do ANYTHING to weaken the tank (after what happened before).

<Understood>

The second series of questions has to do with my old live rock. I had about

50lbs of live rock in the old tank when it failed. I put it in five gallon

buckets (dry) and it has been sitting in my basement for almost 4 years. The

buckets have been open to whatever dust has settled on them (and whatever

bugs or rodents might have crawled over them). I want to use this rock as

base rock, and reseed it with some fresh live rock for the new tank.

<I would do this>

I read through the live rock FAQs again yesterday (2nd time through) and I’m

not sure whether I need to soak these rocks in water with bleach or if it

would be better just to rinse them.

<I'd at least blast them with a hose... No need to bleach likely>

I got the impression from the FAQs that bleaching is needed if the rocks had

something on them you didn’t want (like BGA or crypt, etc.). This was not

the case with mine. I was planning on bleaching them anyway—because they had

been dead so long and sitting in the basement, but a friend told me it would

be better to rinse them off and use them as they are—that anything dead in

them will help the tank cycle.

<I agree w/ your friend>

Do I need to bleach them? Would it be better not to bleach them?

<No bleach>

Thank you so much for all your help,

Eddie

<A pleasure to share. Do please send along a photo of the stand, set up as

it progresses. Bob Fenner>

|

|

Stand; what to use; leveling f's

3/15/16

Hey Bob,

<Ditto>

Separate topic, 50/50 split on research so far.

For a 180 gallon MarineLand tank, that has a rim it sits in, I built a

2x2 inch square aluminum stand for it. It is very level, no deflections

or low spots.

<Impressive!>

Would you still use plywood in between stand and tank?

<Mmm... yes>

The manufacturer stand made of wood just has the trim border, not solid

piece. Half the people I have asked said you just need to support the

trim, which is the part of tank that touches.

<This is so>

Others have said plywood would help distribute weights.

What's your thoughts?

<Well; the ply, foam... something other than metal in the frame, will

give a little bit... sometimes enough to save glass to glass

mal-interaction and significantly reduce torsional problems.

Thanks, bob

<Welcome! Bob Fenner>

Large Tank Stand Construction

9/30/14

I am having a contractor build me a stand for a 250 gallon in -

wall salt tank. He is framing / supporting the weight using 2x4

<Mmm; not what I would do... IF making/fashioning of wood, the uprights

should be four by fours>

and plans on running 2 plywood pieces across the top. Since the tank is

glass and has multiple areas that are plumbed through the bottom, is

there any issue with this design?

<Uhh, no... cut our round holes for the through-puts in the bottom...>

Certainly he will cut out access areas in the plywood for plumbing, but

I have read mixed reviews online about leveraging plywood under the

tank.

The intended purpose was to assist with weight distribution, however I'm

unsure if this will jeopardize the integrity of the glass or create

concerns down the road with the plywood getting wet.

<With enough/sufficient support of the ply underneath... good screws

connecting through it every eight-twelve inches... s/b fine>

Your feedback would be much appreciated.

Jeffrey

<Do have a read through here:

http://wetwebmedia.com/aqstands.htm

and the linked files above. Bob Fenner>

Re: Large Tank Stand Construction

9/30/14

Thank you for your prompt feedback.

<Welcome>

I will tell the contractor that he should use 4x4 for the supports.

Should the plywood be treated or painted to protect against damage from

the salt water?

<... yes; assuredly. Please read where you were referred to>

I also read on your site, many references of placing Styrofoam between

the plywood and the tank. Is this recommended for glass tanks or is this

only used when the tank requires leveling?

<Yes. BobF>

re: Large Tank Stand Construction

9/30/14

Thanks Bob. I spent a good amount of time this evening reading the many

posts on the links you provided. I can't seem to find an explanation of

the benefits to adding Styrofoam on top of the plywood to support the

tank.

The only references I found spoke about existing Styrofoam that was

damaged and another instance to slightly level a tank.

Could you explain why & if I should have my contractor install Styrofoam

above the plywood, as my concern is that the foam would have some "give"

and may cause leveling issues versus the glass being placed directly on

the plywood. If I didn't mention it already it's a 250 gallon glass

aquarium predrilled on both rear corners.

<Depending on the construction of the tank itself, and the surety of the

level and planar qualities of the ply, you may well not find Styrofoam

useful. B>

|

Perfecto 125 Silicone Question

2/17/14

Hello WetWeb!! I recently purchased a new Perfecto reef ready 125

gallon aquarium. I built the stand for it which is level and square.

<Looks neat, clean... is there going to be a mid/front support? Maybe it's

not been installed yet; to allow fitting of the sump>

(Shimmed on a not so level floor). The front span of the stand

is unsupported,

<Mmm; I would over this six foot run...>

I used three 2x4's side by side which were tied to each other with screws

and 5 lag screws. The rear side is a single 2x4 supported every 20

inches. I used a 3/4" sheet of hardwood plywood on top of the stand to

help disperse the load to the frame. When I test filled the tank

there was a small gap, approximately 1/16" between the plywood and the tank.

<Yes; I don't like this>

The stand measured the correct height at the center span and at the ends so

I figured that the gap could be a combination of the tank plastic and my

stand and it would be corrected as the tank and stand settled.

<Not likely>

Well, when I filled the tank (perhaps a bit too quickly), the stand did

not shift. It appeared to hold its shape and all of the dimensions

that I had measured previously. I could not find 1/16" of change

anywhere on the stand. I continued filling the tank, and foolishly did

not pay close enough attention to the gap (of all measurements to ignore).

The gap did not grow, but it didn't shrink.

Only after the tank was full did I notice some changes in the silicone.

Tiny bubbles formed in the silicone. They ran horizontal and split

like spider cracks, maybe 3/16" of an inch long and all of them stopped 1/8"

or more from the outside of the seam. It kind of reminded me of

acrylic crazing. Most of the bubbles were in these spider lines, but

were also apparent as tiny individual bubbles. I thought this to be a

peeling effect that silicone does when its in tension. Reminded me of

pulling out baffles from a sump. In a panic, I immediately started

draining the tank (forgetting to take any pictures). The bubbles

immediately went away as I drained the tank and left no evidence to be

found. While I did not remember to take pictures, I was able

to find a picture online that almost exactly resembles what I saw on my

tank.

<...>

The bubbles started a few inches from the bottom and top of the tank on

both of the front seams. I could not see if they were present on the

back side. So my questions are, have you seen this happen on

new tanks?

<Yes>

Do you think that the tank is safe to use, assuming I correct the stand

such that it supports the entire perimeter of the tank?

<... I would put in the mid/front support... I really don't like the

bubbles; poor workmanship... but the tank is likely fine>

Since I did not observe any shifting in the stand, I'm not really sure

what I should do to fix it. I'd like to maintain the unsupported font

span if possible, so my plan was to replace the front and rear 2x4's with

2x6's for added assurance and give the stand an extra run through

(square/level/planar). How would you recommend I modify the stand?

<See above>

Would you recommend using foam underneath the tank in addition to structural

repair?

<Nope>

Thank you so much!

<Welcome. Bob Fenner>

|

|

|

Aquarium stand <DIY q.> and tank 6/7/13

Hello and good day. I used your site in the past when setting up my first

reef tank with excellent results due to your great advice. I am now setting

up my second one. I will be using a 40 gallon breeder, two 20 gallon long

tanks. All Aqueon tanks. 40 for the display, first 20 for sump and second 20

for refugium. All tied together. I built my own stand for the display tank

and made sure it was as level and planner and straight as it could be.

Here is a picture.

<Very nice indeed>

It is made with a 2x6 frame and cross supports. 3/4" furniture grade plywood

on top with the skirt around the top to hide the tank plastic rim.

The issue I am writing about is this: when I placed my tank on the stand I

noticed there are gaps around the rim where it sits on the stand. One back

corner also has a gap. The gaps I see are here and there. They measure

around 1/64 to 1/32". The one back corner measures close to 1/16". I'm

trying to figure out what I need to do to correct this.

Using a square as a flat edge most gaps don't appear to bad. Checked the

tank the same way and it appears straight. Have assume its all in the top of

the stand. I wanted to know what you would suggest be the best fix.

<I would do nothing... I see you mention foam below>

I was thinking polystyrene foam from Lowes or home depot, rubber mat, 2

part epoxy like you see on bar tops with coins and bottle caps sealed under

the epoxy. What would be the easiest permeant fix and where can I get it?

<Likely there is nothing to be concerned re here. If you don't mind the

looks, the bit of foam all around the frame, stand contact area>

Thanks for your time and response.

Shawn from NEPA

<Bob Fenner from N. Kingston, R.I.>

|

|

Re: Aquarium stand and tank

6/7/13

Thanks for your fast reply. So nothing to worry about. Even the one back

corner is ok not supported due to the 1/16"

gap under it that extends 3-4" away from that corner in each direction? I

<As prev. stated, highly likely not... this difference will settle...>

was actually looking into cork board sheet as of this afternoon. No fear

of tank cracking?

<Only a small bit... on par w/ tripping over ones laces; much less than the

certainty of damage from a car accident. Bob Fenner> |

|

Stand support for 125gallon glass aquarium with dual

corner overflows 4/19/11

Hi I am writing to request guidance for a DIY stand for a

125gallon All Glass Aquarium with dual corner overflows. I

researched WetWebMedia for some time and could not find anything

to help with my situation. I obtained a half completed aquarium

stand on Craigslist.

<? What happened to the other half? Had to ask>

The stand has 2X4s on end surrounding the perimeter of the tank

to hide the trim. The aquarium will not sit on these boards but

just on the inside of them. The bottom of the stand has the same

2x4 arrangement surrounding the outside edge of the stand. The

inside of the perimeter has 1X6 boards attached to the top and

bottom 2x4s vertically so the bottom frame of the glass aquarium

will rest on these 1X6 boards.

<... I don't like this>

There are two 1X6s adjoined together at right angles in each

corner as well as one at the back and front center of the stand.

I did not think this would be strong enough so I added 2X6 boards

by screws to these 1x6 boards and added a top cross piece to

strengthen the stand for the aquarium to rest on.

<Better>

I was also going to add a 3/4" piece of plywood on top of

the stand along with a piece of Styrofoam as recommended by

others.

<Good>

My concern is that the bulkheads will be in the way of the

attached 2x6s in the back corners and would have to cut out some

of the top of the 2x6 to have access to the bulkheads later on. I

wasn't able to provide pictures at the moment but will if

needed for further clarification.

<Please do... All that matters is "how much" of the

wood has to be cut (actually drilled as in circular) away to

accommodate the plumbing to/from the through puts>

Will this cause enough issues to weaken the stand enough?

<Can't tell, or better, render an/my opinion w/o more

detail as to the size, placement of the cut-away material>

What can I do to strengthen it more while still having access to

the bulkheads for future use?

<Perhaps some bracketing... maybe giving up on the returns in

the overflows, running these up over the back of the tank,

outside>

If needed, I can take it all apart and do it completely different

if needed. Thanks so much for the information and advice.

Steve

<Do send along a good drawing and/or image please. Bob

Fenner>

Re Stand support for 125gallon glass aquarium with

dual corner overflows 4/20/11

Hi Bob

<Stephen>

Thanks for getting back to me as fast as you did.

<Welcome>

Here are several photos of the stand including some drawings of

the bulkhead in relation to the stand supports.

<I only see the one .pdf file/drawing, sans indication/s of

where the through puts/cut outs might be. Please re-send the

drawing showing them>

I attempted to get the bulkhead drawings as close to scale as

possible to illustrate how much of the vertical 2x6 stand

supports would need to be trimmed.

<These need to be greatly bolstered... at least doubled in all

corners... and all fastened with screws, not nails... and these

covered to prevent rusting>

The inner circle of the bulkheads are actually the outside

perimeter of the bulkheads that extends through the stand.

<Maybe. Just to introduce the idea here, I would add many more

two-by uprights to support the edges of the tank, particularly if

you're going to go ahead and cut around the two back

corners>

The outer circle of the bulkhead is the nut size for the

bulkheads.

<Am very familiar... you may want to consider

annealing/solventing or screwing something of smaller diameter

(other than the nuts)... to reduce the cut-away areas>

The bulkhead drawing only shows the left back side as the right

side is the mirror image of that and would require the same

amount of 2x6 to be trimmed.

<Please re-send this>

The drawing with the top view shows the center supports as I plan

to place them.

<I'd add several more two by uprights along the support

edge, maybe a couple more laterals (front to back) to more fully

support the ply and Styro top>

The photos did not have the 2x6 supports attached to the 1x6

boards including the center support as I am trimming the boards

to the exact size and have not fitted them in with the stand

yet.

<Understood>

Would I need extra room under the aquarium to work on the

bulkheads for future maintenance or is just drilling enough for

the bulkheads to clear the boards?

<The latter. I would have good help... careful measurement...

with "dropping down" the pre-plumbed fittings here...

onto and into the cut-outs of the stand>

I hope this helps and please let me know any suggestions

including the possibility of starting over using possible 4x4s

and 2x4s.

<I would have made the four corners of 4 bys, but securing two

2 bys (every foot or so) with screws will do here>

Thanks so much for you assistance

Steve

<Happy to assist you, BobF>

|

|

|

Re Stand support for 125gallon glass aquarium with

dual corner overflows 4/21/11

Stephen, in

finding/reviewing your "cut out" drawing (showing where

you intend to make room for the bulkheads, nuts), I do think

you'll be okay if you add the "many" suggested

upright supports (about half the inside edge) and other laterals

across from front to back. BobF

Re: Stand support for 125gallon glass aquarium with

dual corner overflows 4/21/11

Hi Bob

<Stephen>

Thanks for getting back to me again.

<Welcome... as you see, I did find your other drawing...

beneath the first one! When I went to post today>

I was planning on using the aquarium as a South American

freshwater cichlid tank for now with the possibility of saltwater

in the future and wanted to use a wet dry filter for the

freshwater system if it works better than a canister filter/ hang

on the back filter combo. Are wet dry filters more efficient with

less maintenance required than using both canister filters and

hang on the back filters?

<More than good canister filters, like Eheims, less than

hang-ons by and large>

For now I have an Eheim 2080 canister filter and was going to

work it into the overflow by plumbing the canister filter inlet

hose through the drain bulkhead.

<Mmm, I'd just use the stock over the top intake and

return>

Would it work to have the canister filter's intake worked up

inside the overflow through the drain line and rigged into a

Durso standpipe with the canister's strainer at the beginning

of the inlet of the Durso standpipe?

The inlet would be taking water from inside the overflow area.

The return line and spray bar would return back to the aquarium

and plumbed through the return bulkhead or I might just return it

over the back of the aquarium.

<Too likely to have air intake issues...>

I also I wanted the option of putting in a wet dry or sump later

if it works better for a freshwater system versus the canister

filter.

<Just run this independent of the canister>

That brings me to the fish tank stand.

Should I add several more 2x6 uprights for reinforcement mostly

in the back of the tank stand so I can have more room in the

front for access to the canister filter and with installing a

large wet dry system in the future with out having to take the

tank of the stand and putting the wet dry in through the top?

<Yes... all the same "height" of course>

I thought of another possibility after looking at several DIY

aquarium stands on the internet. Would it work better to install

a top and bottom frame of 2x4s running horizontally along the

perimeter of the stand so that the bottom of the tank's frame

and edges are in full contact with the 2x4s underneath?

<Would be better, yes>

The 2x4 frame would also have several 2x4 cross pieces screwed in

for added support. I would still place a 3/4" piece of

plywood and Styrofoam on top of the 2x4 frame with the aquarium

sitting on top of all that. I could also add several 2x6s

vertically and directly underneath the 2x4 frame in the corners

as well as a few in the back and front center parts of the

stand.

The bottom of the stand would have the same 2x4 frame assembly

screwed into the bottom of the 2x6s. I would then wrap the sides

and back with 1/2" plywood and have trim and 2 doors for the

front.

<Ok>

Let me know what you suggest about these options.

<Worth doing, though just adding the uprights... would also

do>

Thanks again!

Steve

<Welcome. BobF>

Re: Stand support for 125gallon glass aquarium with dual

corner overflows 4/21/11

I have a few more questions before heading off and completing the

tank stand as you recommended. Is it possible to use the Eheim in

the normal set up as over the back of the tank but with the

intake being placed in the overflow area or outside it? I want to

reduce the stagnant dead spots in the overflow as much as

possible.

<I really wouldn't be concerned re, and I would not place

the intake here>

I would assume that you would recommend the wet dry filtration

over canisters like the Eheim for biological/mechanical

filtration. Sorry if I am asking the same question again but do

wet dry filters offer more biological/mechanical filtration

capacity and can handle larger fish loads than large canisters

like Eheims?

<Yes, they do... and/but w/ concurrent higher driven

nitrification... i.e., more nitrate production>

What brand of wet dry systems would you recommend for longevity

& efficiency? I have looked at the Proline Aqueon brands as

well as the Eshopps and am not certain which is best or other

brands as well.

Thanks Bob and have a great day!!

<Mmm, I like "custom jobs"... like Marc

Levenson's... for certain features.

But our take on these units can be accessed here:

http://wetwebmedia.com/ca/volume_3/cav3i6/trickle_filters.htm

and the linked files below. Bob Fenner

|

|

question about aquarium stand supports for a 135 gal

glass tank 3/23/11

Hi

<Hello there>

Thank you for offering such an awesome site for questions!

<Why "we're here">

I recently purchased a used 135 gal glass aquarium that I plan to

set up as a salt water tank. I already have a 65 gal and wanted

something bigger...

go figure they are addictive!

<Ah yes>

Anyway, I am trying to keep my cost down so I am building my own

stand, I looked up some stand diagrams for the basics but I

wanted to make sure the stand I am building will hold the

considerable weight of the tank and water etc.

<Good>

as you can see I am not finished yet. I had to take out the

middle leg in the back because it will be in the way of the

plumbing that comes out of the middle bottom of the tank. I have

used 2x4 framing for the top frame, I have cross supports like

the one on the bottom pic at each end and then two more about 18

inches from the ends, again I had one in the middle but had to

remove it for plumbing. I know I need to distribute the weight in

the middle of the tank with another support beam, do I need to

put 2 more on either side of the middle or is it ok to just place

one to the left or right of where the plumbing will come

through?

<Mmm... I would do the putting two more on either side of the

middle back AND add four more supports (2 by 4) one at each

corner... Ideally, these should fit "outside" screwed

against the existing 2 by 4s, and go up underneath the outer lip

of the stand top. Is this clear? I would NOT use the stand as it

is... I would do as I state at this point (otherwise would have

used 4 by 4s at the corners). Further, I would cross brace the

ends with 2 by 4s spanning diagonally the corners on either

side>

I am also concerned with the way I have attached the legs.. they

are screwed in with wood screws 3 at the side an done down from

the top of the support beam.

<To try to be clear, you need the stand to be strongly braced

"in three dimensions"... should it take a jolt, as in

an earthquake or someone running into it in any direction>

I am also trying to figure out how I am going to reinforce the

legs, in the plan I used it has a frame at the bottom to support

the legs but that does not seem sufficient to me?

<Me neither... Again, the diagonal... screwed in place, you

can counter sink the screws, fill in the heads before sealing

all>

I still have to replace the middle leg I removed, I was thinking

of using a sheet plywood paneling for the back from under the

frame to the floor?

<Mmm, why? For strength? I would not do this... you'll

want some air

circulation, indirect light and a way to get plumbing,

electrical... about there>

I looked at my other tank stand and this is how it is done, it

actually has no legs only plywood paneling. how do I brace the

existing legs....

<With the added 2 by 4s at the corners I think you will be

okay here>

I have the wood that I got for the bottom frame but I don't

like the idea of it only being around the bottom portion of the

legs..

seems like it should be braced more in the middle of the legs

from one to the other. If I do this is just a simple cross

support beam between legs sufficient?

<Likely so>

I was also thinking of just paneling the sides like the back

section.. only it would be from leg to leg, would this be good

enough instead of the cross support beam?

<Could work as well...>

I will eventually panel the front of the stand and see if I can

make doors for it.. (see how I do with this part first).

I want to add a sheet of plywood for the floor, do the legs need

to be on top of the plywood to distribute the weight across our

wood flooring (there is concrete under the wood flooring) ?

<I would NOT place a pc. of ply here... too likely to get wet

and rot... of no practical use... However, I would make sure the

area of the 2 by 4 legs touching the floor are well-coated/sealed

for the same reason. Just make sure first that where this stand

and tank are to go is level and planar (by putting the stand on

it, measuring with a long carpenter's level in all two

dimensions on top)>

I am short on cash so I am trying to create this stand as cost

effectively as possible but without compromising the integrity of

the stand. Thanks for any suggestions you may have.

Lisa

<Do please write back if any of this is not clear and

complete. Bob Fenner>

|

|

|

Re: question about aquarium stand supports for a 135

gal glass tank 3/24/11

Bob,

<Lisa>

Ok, let me clarify what I think I understand you to mean :) I think

you are saying to support each leg with another matching 2x4.

<Matching, almost... a bit shorter (like 3.5")...

underneath the long front (and back) lateral, perpendicular to the

existing ones in the corners... screwed to them>

Then for the ends you say to cross brace them, or did I understand

you to say it was ok to simply panel the sides without the cross

brace..

<You could do either... IF the paneling DO use MANY small nails

or good sized (3") wood screws every six inches or so>

and if I need to cross brace it would it look like an X from corner

to corner, or did you mean to cross brace from one end to the other

end?

<One half of the "X" will do>

or did you mean to

put a brace diagonally from the top frame to the leg at each

corner?

<This latter would also do>

Thanks again, I really appreciate the help

Lisa

<I wish we were neighbours. I'd come on over and help

directly. BobF> |

|

stand design -- 3/14/10

Salutations!

<Salud!>

I was wondering if you would have a look at a stand design I have

come up with and answer a few questions/concerns I have

please.

<Sure>

The stand will be used for a 65gal upgrade from my 55gal, and

will house the 55gal as a refugium underneath. I plan all joints

and laminations to be PL Premium joined with screws as fasteners.

The only place lumber will be used on it's flat is the base,

to disperse load. My design is to allow for total access from the

front. (see attached - my scanner produces gifs... hope you will

forgive me.)

<Certainly. Your drawings are clear enough>

My goal is to attach a sump design I found on

http://reefkeeping.com/issues/2008-01/newbie/index.php once I

re-seal my 55gal. My primary concern is deflection of the front

2x4's. Will the laminated 2x4's, having full bearing on

the uprights, be enough to provide support over the span as

indicated?

<Mmm>

Also, will the uprights be enough to carry the compressive

load?

<If they all compress... about the same, should be fine,

but...>

Finally, I value any input/ideas towards my overflow use idea

that you may offer.

Again I thank you for you assistance, and appreciate the

dedication you have to the hobby.

Richard J.C.

<I would add a central vertical (in the front)... that you can

secure with carriage bolts, nuts... or wood screws (brass or

stainless)... so it can be removed if/when you want/need to move

the lower tank/sump. IF the upper

tank were acrylic (not glass) this "extra" support

would not be as necessary, but I would not generally suggest more

than a 24" span w/o such support... definitely not 36"

plus as in here. Cheers, Bob Fenner>

|

|

|

Re: stand design, caffeine 3/14/10

Thank you, Bob, for the fast reply. One other (new) thought

regarding unobstructed access. If sections of angle-iron, 1/4in

thick with 2in flanges, were placed to span the length both front

and back - would that suffice to carry the load?

<Would be better... but...>

or is the centre brace still required?

<IMO, yes... in particular in areas where the ground

moves>

By the way, I learned a valuable lesson regarding my design

send.... coffee first - then send.

<Heeeee!>

My weight estimate was off for the main tank - estimate at 700 to

800 lb for a 65gal, not 1200 to 1400 lbs. I included the weight

of the refugium. Sorry about that. (sipping coffee - rereading -

now send).

Richard J.C.

<1, 3, 7 tri-methylxanthine... the world's most widely

abused psycho-active drug... and my fave xanthophyll. Thank you

for sharing. BobF>

|

|

Large Acrylic Aquarium Stand Question

3/2/2010

Hello All,

<Hi Lisa.>

Unfortunately, I am located in Okinawa, Japan (a small island off

of the main island of Japan)

<Very nice Island, spend many months there when I was in the

USAF>

so finding marine grade materials or teak is rare, expensive, or

hard to find since there is a large language barrier.

<Ok>

This being said, is there anything that is acceptable to use at a

standard hardware store?

<Certainly.>

I can get walnut, birch, plywood, etc, but am not sure if this is

good enough.

<Plywood would actually be best, as it is less likely to warp

that a solid piece of wood.>

It's a very thick, sturdy stand to hold 150 gallons in an

acrylic tank so I don't want to skimp on what I should use. I

have included a picture of what I have built so far with my

husband being the sander man.

<The stand looks very sturdy. Get a nice piece of plywood and

stain it, and you should be fine.>

<MikeV>

|

Very nice! Very nice! |

DIY aquarium stand 10/31/08 Quick question, I

recently built my own aquarium stand to normal measurements and

allowing a 1/2 in space around for wiggle room. But here is the

problem. When you lean on the front of the stand it leans a little

forward, also I built it taller than the standard size ( I went with 40

inches). Now should I put a 50 lb bag of sand in the inside of the

stand to counter the lean or will it correct its self when the tank is

filled also the stand is on carpet not by choice but because it is in

an apartment <By leaning forward, I assume you mean it is not

sitting flat/flush on the floor? If so either the stand or the floor is

indeed not planar. You will need to shim this out just like a leveling

issue, ideally with a continuous piece of wood on the bottom of the

stand, or between the stand and the floor. See:

http://wetwebmedia.com/aqstdleveling.htm If it is wobbly just because

it is sitting on the carpet, fill the tank partially and then check for

wobble/level and proceed from there. Scott V.>

DIY stand 9/9/08 I am planning on

constructing a DIY stand. Will be made completely of wood, most likely

2x8's and 2x4's (placed on end vs. flat)-with glue/screws.

Would be for a 280 gallon glass only tank. Stand dimensions likely

72"Lx30"Wx42"H. I have a few questions regarding. Is

there any advantage/disadvantage to attaching a plywood base to the

bottom of the stand frame? I've seen many tank stands without a

base, just 2x4's as the base. What would be your recommendation?

What thickness of plywood? I'm planning on a base for the top of

the stand, though being that it's a glass tank, it may not be

needed. However, this is a large DIY glass only tank-all panels resting

on bottom plate (tank). Given this information, would you recommend a

plywood/foam base for the top of the stand? <I would always use a

base on a stand just because it is more visually appealing. It is not

necessary though. Also I would use 1/2 plywood for strength. There are

many helpful websites on this topic and you can look at many different

aquarium stands online. Good luck with your project,

IanB><<... what about a referral here? RMF>> Thank

you!

| Stand and Floor Reinforcements for a

125g Tank -- 05/21/08 I looked through your archives and

found one similar and yet fundamentally different question.

<<Okay>> Here I include the page link:

http://www.wetwebmedia.com/diystands.htm. Use a find and look for

poles in reference. <<?>> On to my question. I have

been advised and wish to call upon any experience over at

WetWebMedia on this subject as a second opinion. <<I'll

be happy to proffer mine>> Sorry about Length. <<No

worries>> I live in a home built for the Dept of Ag in 1928.

This structure has no discernible level issues at the floor level.

I have used my 2 foot level all over the area that will house my

new 125 gal reef. <<Mmm'¦a longer level (or

attachment of your level to a longer and straight 2x4) would likely

reveal 'some' deflection'¦but it sounds like this

is not a great concern here>> Currently a 75 gallon inhabits

this area, and what a day it will be switching over. I am unable to

find deflection in the floor. In fact I thought I saw deflection

but... it's splitting hairs to some degree as we are talking

about a bubble that appears centered. <<Some deflection is to

be expected'¦even in 'new'

construction'¦but as long as it is not to the extreme, it

can be dealt with>> Am I worrying too much at this level?

<<Does sound as if so'¦based on what you have found

thus far>> Being 80 years old and no measurable deflection in

the floor, I am hoping this is good. <<Yes'¦a bigger

concern may be whether the original builder used a large enough

floor joist, as I suspect what you have would not be suitable/would

be too small by 'today's' building codes.

But'¦this too can be dealt with if it is the case. At any

rate, whether up to code or not, I would plan to add some

additional support to the floor from under the house just for the

peace of mind>> I am on an exterior wall. Outside this wall

behind the tank is a small sunroom. It has no basement section

below it and no second floor unlike the rest of the house. It is

only 2/3 the length of that exterior wall. This still counts as

load bearing, does it not? <<I would expect the wall to be a

load-bearing wall, yes'¦but, that does not mean the floor

adjacent to it can bear a larger load without additional support. A

load-bearing wall is designed to take the load 'on top of'

the wall'¦the 'support' for this wall does not

extend to the flooring adjacent which relies on the size and

spacing of the floor joists (along with their method of attachment)

to determine its load-bearing capacity>> The unfortunate part

is that I simply cannot place it perpendicular to the joists, which

happen every 18 inches. I can bring it 18 from that exterior wall

to insure it is over a joist. I was advised that it probably was

not a huge deal, but that for comfort I could go into the basement

and add a sheet of OSB right under the tank, against the ceiling

and use 4 adjustable steel joists rated at 19000 @ at each corner

of the OSB to reinforce the floor. <<Okay, let me see if I

can get this straight'¦ By 'steel joists' I think

you mean adjustable steel post-jacks rated at 19,000lbs each. These

jacks/posts would work very well, but I WOULD NOT use/trust the OSB

to support these/the floor. What 'I' recommend is

this'¦ Since the tank will be positioned parallel to the

floor joists'¦place the tank as centered as possible over

two joists (running parallel). Note these joists and get two wooden

4x4 posts that are long enough to span these two joists AND reach

one joist to EACH side (i.e. -- span four joists with each 4x4).

Position the 4x4 timbers under joists (spanning the four joists as

described) and about a foot in from where each end of the tank will

be and position and support each 4x4 in the middle with a post-jack

(one jack per 4x4 will suffice)>> I was told that this was

completely overkill but effective. Can anyone concur? <<To

reiterate, the OSB will not suffice'¦what 'I describe

is not overkill'¦but is effective>> This basement is

concrete but finished, the ceiling is finished with plaster and

slats. <<Mmm'¦you may want to use a sheet of plywood

between the 4x4 timbers and the ceiling then to spread the load

more evenly'¦but even then, you will still likely have

compression marks in the ceiling>> The 75 is here with 20g

sump currently. Pictures are avail if needed. I have built my stand

using this plan:

http://www.reefcentral.com/forums/showthread.php?s=&threadid=1169964&perpage=25&pagenumber=1.

It is a lot to ask, but I would appreciate if you just look at the

picture and first post. If not though, I do understand. <<Had

a look'¦this appears to be a good and sturdy

design>> I added two 2x4 vertical legs in the front and back.

They occur at about 24 inches from either side and this tank is

72", but the stand to be 73". It's probably overkill

given physics and the 2x6's but why skimp at this juncture only

to experience tragedy. <<Indeed'¦a bit of

over-engineering can be very comforting>> On the other hand

perhaps I am missing something, how do you view this plan?

<<I don't think you have missed anything re the

stand'¦this design should serve quite well>> I will

keep the sump on a whole other floor from this so no worries there.

I appreciate your time and help. <<A pleasure to

share>> If ever I can help please let me know I will gladly

return what I am able to. Ian <<Ian'¦do get back to

me if any of my explanation re the joists support is not

clear/needs further explanation. Good luck with your project.

EricR>> |

|

| Re: Stand and Floor Reinforcements for

a 125g Tank -- 05/22/08 Eric, Thank you for your quick and

informative reply! <<Quite welcome, Ian>> I have

included our previous correspondence below. <<Thank you for

this>> To acknowledge your questions. I just wanted to link

to the mentioned archives in case you needed reference. <<Ah

yes>> **By 'steel joists' I think you mean adjustable

steel post-jacks rated at 19,000lbs each.** Indeed those adjustable

joists are the ones in question. <<To be clear

here'¦ 'Joists' are the 2x material spanning from

wall to wall and supporting the floor above and (in this case) to

which your lath and plaster basement ceiling is attached. The

post-jacks are 'not' joists, but will be used to support

the joists from below>> **Mmm'¦you may want to use a

sheet of plywood between the 4x4 timbers and the ceiling then to

spread the load more evenly'¦but even then, you will still

likely have compression marks in the ceiling** I do not mind the

compression marks and I checked with the home office and they'd

rather the floor is supported. <<Very good>> The

plaster is old hat and can easily be replaced by sheet rock.

<<Unless you are a purist, yes'¦though if you've

never done it before, you're definition of 'easily'

might change [grin] >> So, I do not believe I can go out

enough, given the rooms setup, to be situated so that I could span

a joist on each side of the tank from underneath. At least not

without problems with the rest of the rooms objects and

inhabitants. Well, being finished it is hard to see what is where.

Is it uniform to have a stud just after the load bearing wall? Say

within a couple of inches? If so I could just barely do it, but if

not... <<You stated in your earlier query that you could not

place the tank perpendicular to the floor joists'¦this

would mean you will be placing the tank 'parallel' to the

joists, yes? So'¦what I am trying to convey is that you

should position the 4x4 support timbers to span at least one joist

to either side of the tank>> The one part I was unsure of

from your description is that your suggesting the 4x4's should

be placed from underneath approximately 1 foot in from each end of

the tank right? <<Below the floor joists and against the

basement ceiling, yes (supported by the jack posts)>> And

that the joist should be directly under the tank, which should be

in the center of the 4x4? <<I think you are confusing

terminology here (refer to my earlier statement re joists and

jack-posts). If you can run the tank centered over a parallel joist

that would be good, but at the least, span and support a joist to

either side of the tank from below with the 4x4. And'¦what

should be centered on the 4x4 timber is the

'jack-post''¦ Are we clear here?>> What if I

cannot as described above, achieve a definite center due to my

inability to get the tank out that far from the wall? <<If

the tank is not going to be placed perpendicular to the floor

joists as you stated, I don't understand what this has to do

with its distance from the wall? Tell me'¦how is this tank

going to be placed in reference to the outside wall we discussed

earlier'¦and'¦in which direction do the floor

joists run in relation to this outside wall?>> I looked

downstairs and the plaster is actually on a metal screen like

material, which would have to be against the joists. I asked the

maintenance guy about what size joists are in these homes. I would

assume with the floor being so thick, around a foot, the plaster,

and the original use of cast iron radiators that they must be at

least 2x6's but my answer should be in soon. <<Current

code probably requires a 2x10 joist these days (can vary by

region/state/county)'¦but not to worry'¦if

installed properly, the post-jacks and 4x4 timbers will supply

plenty of support>> Ian <<As before, get back to me if

any of this is not clear or we have any misunderstandings. I would

also very much suggest you invest a couple hundred bucks to have a

structural engineer take a look at what you want to do and to

advise on the support system re. The peace of mind alone is well

worth the investment'¦but having someone there to put

their eyes on your project and to explain 'first-hand' what

needs to be done can make all the difference. Cheers, Eric

Russell>> |

Tank set up, stand construction

05/19/08 Good Evening, whomever answers this query! <Hello

to you Fish Nut... BobF out in the land of the Pharoahs currently> I

have recently purchased a used 75 gallon (standard size) tank ($60,

couldn't pass it up...) to upgrade my existing 55 gallon that

currently holds 5 Discus, all about 2.5- 3.5 inches in length, and a

few Hatchet fish. I will be purchasing more fish, however I'm still

researching/deciding as to what I'm looking for exactly. <Mmm,

I'd leave most all the room here for your growing Discus>

Anyhoo, I took the tank home, and did some measurements on my existing

stand, and it appears the width (well.. from front to back) of the tank

is too wide. I'm short by about 1/2 inch or so, probably a bit

less. If I were too purchase a thick sheet of wood that will

'extend' the top of the surface of my stand, do you think this

will work out/be safe? <Yes... Plywood (marine grade is best) of one

inch or 2.5 cm. thereabouts is about right. I'd seal it with

urethane, polyurethane...> I'm leaning toward 'yes' but

with about 750+ pounds of water, rocks, etc weight resting on it, I

want to be completely sure. Also, is it worth the effort and risk to

upgrade? To me, It's not worth spending another $200 or so for a

quality stand that is made for a 75 gallon tank, but it's worth a

few dollars the wood will cost. Thanks for the help! Eric <Do you

have concerns that the current stand will not support the additional

weight of the new tank et al. gear to be used? I might well test this

out in the street or garage with an overage of weight first. Bob

Fenner>

Re: Stand size diff., weight

05/20/08 Bob, <Eric> Thanks for the quick answers. I

appreciate the help. I'm confident the current stand will support

the weight of the tank, it's just a matter of the width being too

'wide' is all. I'll have to look into the marine grade

plywood that I can coat with polyurethane. Do you think the 75 gallon

will allow adding additional fish? <Compared with the 55? Oh yes...

wouldn't we all like 55-75/55 difference in our pay? Time on the

planet?> I recently read (well; re-read) the article on Discus in

WWM. Very helpful. Thanks again. Eric <Welcome/Welkomen BobF, in

Deutschlund>

Questions About DIY Tank Stand -- 11/30/07

Dear WWM Crew, <<Hello Brian>> Please allow me to start off

by thanking you for saving me much grief in my saltwater endeavors. I

find this hobby to be at once delightfully confounding, and sublimely

rewarding, and having a resource such as WWM as close as my fingertips

helps immeasurably. <<We are all pleased to be of service>>

Now, on to my query. I have recently decided to build what, in my

opinion, could be considered a furniture quality aquarium stand for my

37 gallon acrylic flat-back hexagon reef tank. <<Neat! Am a bit

of a woodworker myself>> I have tried to err on the side of

caution, and build with the idea that this will be a functional piece

of furniture, as well as a safe, level, and planar stand for my reef

and its inhabitants. <<As it should be>> As stated earlier,

I currently have a 37 gallon acrylic which is 13 inches wide, 36 inches

long, and 18 inches deep. I have designed this stand with the intention

of being able to upgrade to either a 55 gallon glass tank, or a custom

made acrylic tank in the future. <<Ah, an eye for the

future'¦smart move>> My current design is for a stand 6

feet in length, 18 and one half inches wide and 30 inches tall. I have

built the frame out of standard 2x4 lumber from the local Lowes. For

the top and bottom frames, I constructed 2x4 rectangles of the desired

dimensions, the 2x4s placed "on edge", rather than flat, with

the ends butt jointed. <<Mmm'¦do use a good waterproof

glue at the joints along with your mechanical fasteners (a

'Polyurethane' would be best), and maybe consider adding some

galvanized 'hurricane' braces at the inside corners like those

used for deck/house construction, if possible. You may fine you will

need to 'inlay' the braces to allow for smooth fitting of the

external skin panels'¦depending on the type used and your

design. Also'¦I would 'double-up' the 2x4s on the long

dimensions, especially in anticipation of a larger tank. Simply

'sister' a second 2x4 to the first with glue and

screws'¦will actually be stronger/deflect less than if you had

used 4-by lumber>> A horizontal cross member, at 15 and one half

inch length of 2x4, has been placed every one foot, along the entire

length of the frames. <<Excellent'¦this acrylic tank

will need 'full' support over the entire bottom of the

tank>> For the vertical supports at each corner, I used 30 inch

lengths of 4x4 lumber, notching out the very top of each vertical post,

to accept the top and bottom frames flush at each corner. <<Very

good>> I also placed a vertical support centered at 36 inches

horizontally in both the front and back of the stand.

<<Ah'¦okay, good>> As an added layer of security,

I have diagonally braced each of the corner posts, using a piece of 2x4

cut on a 45 degree angle attached to both the post and the top and

bottom frames. <<I see'¦ Can't hurt, though

attachment to both the top and bottom frames would likely have been

sufficient. I have built a few tank stands myself, including the one my

current 375g reef sits upon'¦a bit of over-engineering is not

a bad thing>> The surface for tank stand is a 1 inch thick piece

of oak plywood 72 and one half inches long, by 18 and one half inches

wide, secured to the rest of the frame using a combination of wood

screws, and glue. <<Holy-cow, mate'¦you're gonna

need a few friends to move this tank stand>> I plan on placing

the finished cabinet on a 3/4 inch piece of solid oak plywood which

will be one half inch larger than the base of the cabinet, for even

distribution of weight. All joints and surfaces were made square and

planar using a handheld power planer. (A must have for even an amateur

woodworker!) <<Hee-hee! I don't know about 'a

must''¦but definitely a neat/handy gadget!>> I am

quite certain that this stand is engineered well enough to support the

weight of the 37 gallon for many, many years to come.

<<Okay>> My concern is for future upgrade possibilities. Do

you feel that this stand, as described, will be able to support the

possible weight of say, a 55 gallon, with a very liberal weight

estimate of 700 pounds, or even a 75 gallon? <<Double-up the

frame members on the long dimensions as earlier suggested and I think

you'll be fine/have better piece of mind>> I apologize for

the length of my query. <<No worries>> I have tried, to the

best of my abilities to be as clear and concise and possible.

<<This is greatly appreciated>> I eagerly await your

response/feedback. <<On its way'¦>> With best

wishes for a safe and happy holiday season, Brian <<And to you in

kind. Eric Russell>>

Question Concerning DIY Tank Stand 11/29/07

Dear WWM Crew, <Hello, Scott V. with you.> Please allow me to

start off by thanking you for saving me much grief in my saltwater

endeavors. I find this hobby to be at once delightfully confounding,

and sublimely rewarding, and having a resource such as WWM as close as

my fingertips helps immeasurably. <Much appreciated Brian, this is

one uniquely amazing hobby.> Now, on to my query. I have recently

decided to build what, in my opinion, could be considered a furniture

quality aquarium stand for my 37 gallon acrylic flat-back hexagon reef

tank. I have tried to err on the side of caution, and build with the

idea that this will be a functional piece of furniture, as well as a

safe, level, and planar stand for my reef and it's inhabitants.

<Sounds nice.> As stated earlier, I currently have a 37 gallon

acrylic which is 13 inches wide, 36 inches long, and 18 inches deep. I

have designed this stand with the intention of being able to upgrade to

either a 55 gallon glass tank, or a custom made acrylic tank in the

future. My current design is for a stand 6 feet in length, 18 and one

half inches wide, and 30 inches tall. I have built the frame out of

standard 2x4 lumber from the local Lowes. For the top and bottom

frames, I constructed 2x4 rectangles of the desired dimensions, the

2x4s placed "on edge", rather than flat, with the ends butt

jointed. A horizontal cross member, a 15 and one half inch length of

2x4, has been placed every one foot, along the entire length of the

frames. For the vertical supports at each corner, I used 30 inch

lengths of 4x4 lumber, notching out the very top of each vertical post,

to accept the top and bottom frames flush at each corner. I also place

a vertical support centered at 36 inches horizontally in both the front

and back of the stand. As an added layer of security, I have diagonally

braced each of the corner posts, using a piece of 2x4 cut on a 45

degree angle attached to both the post and the top and bottom frames. I

plan on placing the finished cabinet on a 3/4 inch piece of solid oak

plywood which will be one half inch larger than the base of the

cabinet, for even distribution of weight. All joints and surfaces were

made square and planar using a handheld power planer. (A must have for

even an amateur woodworker!) <Must admit I have yet to get one!>

I am quite certain that this stand is engineered well enough to support

the weight of the 37 gallon for many, many years to come. My concern is

for future upgrade possibilities. Do you feel that this stand, as

described, will be able to support the possible weight of say, a 55

gallon, with a very liberal weight estimate of 700 pounds, or even a 75

gallon? <No doubt it could hold an even larger tank. It sounds like

you have a very sound design. Most commercially available stands are

under built compared to your design. Just be sure that you also have

plywood on the top of the stand. An acrylic aquarium must be supported

over the entire bottom, not just the perimeter as with glass tanks.>

I apologize for the length of my query. I have tried, to the best of my

abilities to be as clear and concise and possible. I eagerly await your

response/feedback. With best wishes for a safe and happy holiday

season, Brian <Thank you, again much appreciated. You have a solid

design that will likely outlast the tank itself. Have fun building, and

watch those fingers (I should have bought that planer). Scott

V.>

75 gal. fish tank... Stand, canopy const. Qs

I am in the process of starting up a 75 gal tank. and am going to build

the stand and canopy myself. <A good project> I found a site

where a guy built his and gave the step by step, but am wondering if

four 4x4's for the legs will strong enough to support it. <Oh

yes... most commercial stands for this sized system are of 2 bys...>

also if i should only use one 2x4 on each side of the front and back of

stand for middle support. <Can be done> also I need to find a

good lighting fixture for the canopy. a website i was going to purchase

one from said to make sure there is enough air flow for the light so it

does not overheat but how do i know if there is enough air flow for the

light, or do i install it and wait for it to explode if it does get to

hot. and i also need to know what type to buy as well because i want to

do a reef tank, so if you could give me some recommendations i would

appreciate it thank you. <Please read here:

http://wetwebmedia.com/marine/setup/index.htm The second tray down...

Bob Fenner>

Stand, design, const. 6/5/07 Dear WWM Crew <Joey>

Hello again guys and gals love the site and find myself spending more

and more time on it everyday keep up the excellent work. Quick update I

wrote you once earlier with an Oscar problem my dear buddy Lorikai had

a chunk missing from his mouth and has been healing quite nicely

without much intervention other than weekly partial water changes as

you suggested you guys rock. I did however notice what possibly caused

the injury is that sometimes when feeding the Oscar feels the need to

violently gulp his food and I think the water level was to high and a

piece of food could of been up against the plastic edge and caused his

laceration. problem solved I now keep the water level a good half inch

below this edge now. <Good move> The reason I am writing today is

I am moving forward with my aquarium and would like some advice. I have

recently acquired a 90 gallon for my Oscar and Pacu. Which in the

future I plan to turn into a SW tank once I have acquired and even

larger tank for my boys. That being said now I need a place to put the

bloody thing. I have scoured some LFS and online stores to find nothing

really to my liking in a stand. They all seem to be either overpriced,

poor quality, or just plain ugly and sometimes all of the above. So I

am now going down the DIY path because I know I can make something way

better. I have found this site just recently and thought it was pretty

amazing http://www.fishandtips.com/index.php and here is also a link to

the stand I am planning to build

http://www.fishandtips.com/step1/step1.php?Step1=&Step2=&Step3=&add1=&

;Key=&Length=48&Width=18&Height=25&StandHeight=30&add1=checked&

amp;Step1=checked&Step2=checked&Step3=checked <Very nice

plans> Sorry its such a long link. I was wondering what your

thoughts are on this build from what I can see it looks pretty solid

and have thought about putting 2 more 4"x4"x11" poles in

one on the top and one on the bottom although not sure if entirely

necessary or not. <I would add these... for greater stability,

strength against lateral movement> I am also glad I looked over some

info on your site because this site recommended pressure treated lumber

to avoid rotting and I knew pressure treated wood was poisonous but the

thought never crossed my mind about seeping into my system. <I would

coat this... Varathane, Urethane...> So I will be using an untreated

wood hopefully some nice kiln dried oak. I am thinking about using a

faux marble wallpaper <Oh!> I have found online and coating that

with a high gloss polyurethane. Is this feasible and if so do I need to

do anything else as far as water proofing the untreated wood or would

the polyurethane cover it I am unsure of this. Thanks in advance and

once again you guys rule. Yours Truly, > Joey <The biggest change

I would make to these plans would be to use countersinking and carriage

bolts, nuts and washers in the place of the specified wood screws. Bob

Fenner>

Using Treated Wood For Aquarium Structures - 02/04/07

Dearest Bob and Friends, <<Greetings>> Wishing good health

to all; I have been on a very strict diet for 3 weeks.. Argh!)

<<I hate diets...>> I have finished building a very strong

stand for a new 90-gal I will be setting up. <<Cool!>> I am

quite sure that I made a mistake in my wood selection.

<<Oh?>> I used 5x5 treated wood. Afterwards I found out

that treated wood has a poison biocide stain (green) on it.

<<Mmm, indeed...is why it is called "treated." The use

of arsenic (chromated copper arsenate) was banned for residential use

in 2004, the treated wood available to homeowners (hobbyists) today

contains either alkaline copper quat or copper azole. While much less

toxic to us than the arsenic based treatment, you'll notice the

common ingredient is copper...sometimes as high as 96%. Obviously you

don't want this leaching in to your tank>> This is a problem

right? <<It can be yes...and is why I chose to not use treated

lumber when building my in-wall reef display>> Can I simply

varnish over? <<I don't recommend this...it just won't

last in this environment, and the wood is still likely too

"wet" anyway. Your best option is to use a penetrating oil

stain to seal the wood that can easily be renewed as needed>>

Another problem is that the wood I used was not 100% dry when I got it.

<<Ah, yes...treated and kiln-dried wood is sometimes available,

but more often than not the wood at the home centers (Lowe's/HD) is

not "dried" and is only hours/days old after the treatment

process>> Now it seems to have finished drying since it was built

and now the areas where the tank sits on the stand is no longer planar.

<<Not unusual...treated wood is usually meant for

"rough" construction and is not the best

"cuts"...couple that with the extremely high moisture content

and bowing/twisting is inevitable. Another reason for using untreated

and kiln-dried wood>> Off by 1/8 inch at some places. I tried to

level off using a hand sander and files but I think I made it worse.

<<You're best option here is to start over with better wood I

think>> The wood has also cracked in some areas but I doubt that

is of any worry. <<Mmm, I don't agree...there will be an

awful lot of weight on this stand>> I honestly think my stand

could hold a train car. (5x5 wood, secured using 7 inch 3/8 wood

screws, and wood glue, structure is all boxed in) <<Ah...but is

all "moot" if it is not level and planar>> At this

point I'm thinking that I could simply place a 1/4 inch thick

rubber strip under the perimeter (this is a perimeter trim tank) of the

tank to compensate for my non-planar mess! <<Mmm, I don't

think this is a good solution here>> I think I remember reading

your advice against this but I think at this point I'm ready to

accept a non-ideal solution. <<Are you ready to accept having the

tank burst?>> I think the odds of me bringing this planar using

hand tools is slim. <<Likely, yes>> It is not as easy and

is actually quite easy to make worse. <<Indeed...and reason

enough to chalk this up as a "learning experience" and just

start over>> Thank you very much for your time. <<Happy to

share. EricR>> Tristan

Tank stand construction questions 9/20/05 Bob,

<Greg> First, your website is great! I have gotten tons of great

info over the past few years. thanks. <Welcome> I have 2

(unrelated) stand construction questions. 1.) I recently moved my 120g

reef Oceanic reef tank. In the rush of moving/setting it back up the

tank stand did not get perfectly level. <Mmmm,

"perfectly?"... oh, I see below> There are several places

where a sheet or two of paper would fit between the tank and the stand,

after 8 weeks it still hasn't settled in. To fix this right, it

seems I would have to take the tank down and fix level the stand - is

this worth doing? Is there any other recommended fix? <Mmm, you

might get by here by "cheating" a bit with placing some

freshwater under the low spots... having the hopefully wood stand swell

some> 2.) I need to construct a stand for a 225g acrylic reef tank,

60 X 24 X 36 (my guess is 3000lbs?). <A bit less likely... a few

hundred pounds shy> I have a 48in, 55g tank I would like to use as

the sump. To make access easy underneath, would 2X6 be sufficient to

support the 60in span for this tank? <Mmm, no... I would go with

four by... carriage bolt together...> If not all 60in, what would be

the max. spanning distance you would recommend for a 2X6 for this tank?

thanks. Greg <Would be nice to be able to "angle in" the

four foot long 55... and can likely be done with a bit of planning,

making a six legged stand... with the one center front middle upright

staggered off to one side a bit... I would make these four-bys as

well... Bob Fenner>

Stand Construction Question

8/19/05 Hi All, I've been in this tremendous hobby for over

5 yrs now and am more than hooked you could say. I have 2 55g tanks and

some smaller 10g tanks also. I have gotten the go ahead for a 300 g

tank in the lounge room and am putting it in the corner of the room. It

will be a pentagon shape. <Congrats!> I think it will be

4'x4'x18"x18" and 3'10" across the front and

26" high, with a sump underneath of what size I'm not sure

yet. It depends on the room I have as much as possible. <Sounds

great!> My question is: are there any particular plans for a stand

this size? I have shored up the floor after asking an engineer and am

confident of building it myself either out of wood or steel. Which do

you think is easiest and best? <Glad to hear that you have shored up

the floor. Wood and steel are both great materials for building a

stand, but each has some advantages and disadvantages. Most folks

don't consider welding the steel to be a Do It Yourself project and

it can rust. It is also harder to add an attractive facade to. Wood is

easier to work with, will never rust and is easy to modify, but it can

warp and/or rot. Given the unusual shape of your tank and the unusual

angles, it may not be much harder to go with steel. If you do choose

steel, I recommend having it powder coated, or if this service is not

available in your area, painted with a high quality epoxy paint. As for

plans, you won't find them specifically for this unusual tank, but

you may find some general tips with a Google search.> I am getting

the tank builder to make the tank in my lounge room and then it will be

just a case of lifting it up onto the stand, with a lot of help from

some friends I hope. Do I need to have a center piece underneath to

hold the middle up because if so, I will lose room for my sump?

<Probably not. Most tanks are designed to be supported only around

the perimeter to avoid pressure points on the bottom pane. Your tank

builder should be able to advise you on this and should use think

enough glass to be self supporting.> Thanks very much for your

wonderful and helpful site I read it everyday. Yours Scotty Tasmania

Australia <Glad you have benefited! Best Regards. AdamC.>

Place Foam under Acrylic tank? DIY Stand Question - 10/23/05

Hiya Ladies and Gents! Before I get to my question, I must say again

how right you are and I shouldn't have even bought a 13 gallon

marine aquarium. Living in a smaller Japanese house, I wasn't sure

how it would fit, but now it is the focal point of the house! While

I've had great success with it thus far, it would have been

surprisingly cheaper to 'go large' but I couldn't

understand the reasoning back then. Now I see clearly. I've learned

a lot about marine aquariums in a short time. 3-5 hours of nightly

'net' reading and a front row seat in front of the tank. Yes,

it's possible to be successful. No, I wouldn't suggest it to a

beginner. Ok, to the first question. I upgraded to a 66 gallon acrylic

tank today. Going to make my own stand (a few years and lots of tools

in the hobby to help me out). The LFS told me NOT to use a foam mat

under an acrylic tank as it will eventually begin to chemically react

and may 'glue' it self to it after a few years. Is this true?

Or is there another form of 'forgiving material' to use? Next

question is (if I can't use foam), what kind of finish am I able to

use for the stand top? A lacquer? Polyurethane finish? Bare wood (hmmm

unprotected wood and water = bad idea me thinks) Will these eventually

have chemical reactions to the acrylic? Thank you again for the

priceless resource! <Thank you for the kind words. Dana, I've

always used Styrofoam sheeting to place under my tank. Works well and

does not stick to the acrylic. As for finish, polyurethane is your best

bet with no negative effects. James (Salty Dog)>

Stand for 125G acrylic tank - 03/11/2006 Hi Crew,

<Tom> I've been reading up on DIY stands and seeing mention

of 2x4 and 2x6 framing & cross bracing required. The cabinet stands

I'm seeing in a couple of LFS's appear to be made of 3/4"

plywood sides, with a 3/4" plywood top to support the tank.

<Some of them, yes> I've seen this type of construction on

stands up to 24" deep (front to back) and 48-72" long, with

no other bracing...is this adequate for a tank that could weigh nearly

a ton? <Mmm, well... as a person posting "things" on an

open forum (the Net)... no. Much safer to encourage folks to use more

sturdy timbers, screw and/or bolt/nut together... using ply and such

for fascias> I'm planning to build a stand and would like to

avoid losing cabinet space to center bracing & divider walls inside

the cabinet, if I can. If one sheet is not enough, would two sheets of

3/4" plywood, or 1.5" total, be strong enough to support a

125G tank with only perimeter support? Thanks, Tom <Not IMO Tom...

Have you visited OzReef.org? Much good DIY info. there re aquarium

matters... As you state, this is a lot of weight... and in areas where

the ground shakes, or that such constructs might suffer lateral force

otherwise... I'd go with bracing the stand in all dimensions...

strongly. Bob Fenner>

Aquarium Stand 3/3/06 Hi Bob A friend who owns a

welding shop is planning on building an aquarium stand for my 125

gallon six foot tank. <Nice> He is using 2 inch square tubing for

the frame. The question he asked and I could not answer was: is it

better to build it with metal tubing all around the base of the

aquarium's foot print which touches the floor or build it with four

or six legs? <Mmm, better the latter... particularly in settings

where the flooring is not level, planar or worse... differentially

so... as in on wood supported by wood framing...> I thought it might

distribute the weight more not being on four or six legs but have it

resting on two inch tubing all around the base of the tank. I thought

it might be easier to level on four legs though. <Mmm, not really...

better (if necessary) to employ large shims under the longer,

continuous supports... and to measure with the tank filled and

empty...> Any help would be greatly appreciated as all the DIY

instructions I have found are for wooden stands. Thank you in advance.

Leta <Do see the excellent DIY site which is Ozreef.org for much

valuable input here. Bob Fenner>

Stand Construction Question - 1/30/2006 Good morning

Crew! Hope your weekend is going well. <All over... but wait! I

don't have a day job... every day's like a weekend day!> I

am in the process of building a new stand for my 200 GAL Oceanic glass

tank. The tank is 7' X 2' x 2' and was bought as a used

setup including the stand (but is looks like it has been rode hard and

put up wet! :-) ) <Can be dangerous...> Anyway, on to the

question. Since it is a glass aquarium, I understand that it is mostly

perimeter braced (i.e. normally just sitting on 2X4's around the

edges and the bottom glass bowing slightly is not a major concern.

<Yes> However, since it has 4 holes drilled in the bottom (which

I will be plugging up and drilling the back panel for my overflows and

returns) should I: A. Build the "standard" stand with only

perimeter support like this: http://i5.photobucket.com/albums/y195/navajo001/frame.jpg B.

Build a stand with extra cross bracing for the tank to rest on like

this: http://i5.photobucket.com/albums/y195/navajo001/framewithxbrace.jpg

C. Build a stand with the extra cross bracing (option B) and add

3/4" plywood on the top for the tank to rest on. <C. is your

best choice... or B., with a good/thicker piece of

"Styrofoam" under the edge and floating bottom> Your

assistance (once again) will be much appreciated. As always, your

efforts in this hobby are OUTSTANDING and the level of

concern/knowledge are truly appreciated. Keep up the good work and know

that countless lives (and probably marriages) have been saved/enriched

by your efforts. Tom (The Tool Man) <As you know Tom... more support